Get to know the industrial chains

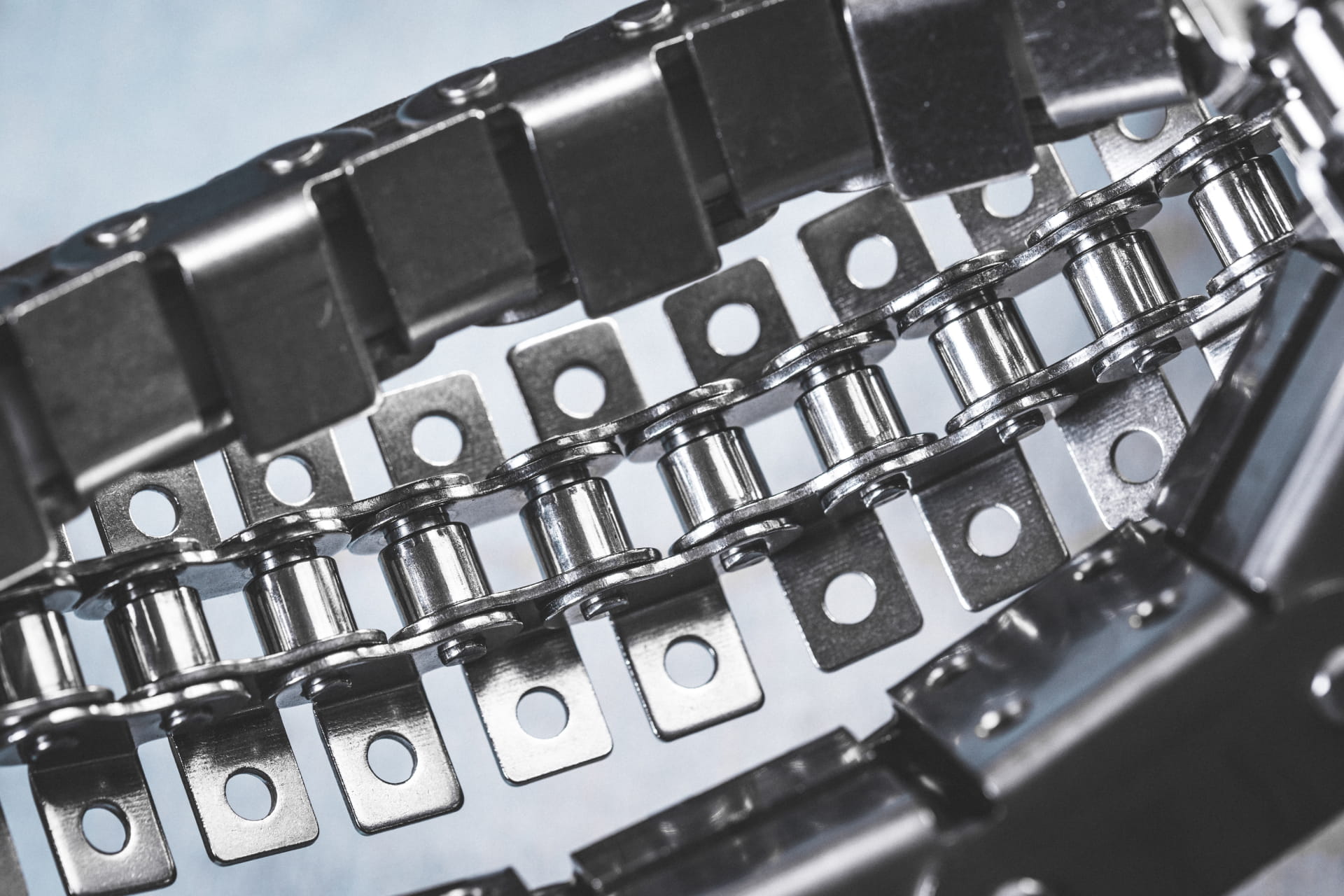

Hello again! Today is the first post of our new section “Get to know the industrial chains”. In this section we will try to familiarise you with one Iris Chains industrial chain in each section, in this case roller chains with attachments and extended pins.

Within this type of chain, we have different materials depending on the intended use of the chain. Therefore, it is necessary to choose the material that best suits the characteristics of the machine and its application. Mainly, the types of materials used in the manufacture of this chain are steel, those with a special bath (Delta tone, nickel…), stainless steel and steel with “paint”.

It should be noted that all chains can be the same size regardless of the material from which they are made. However, the material is a key factor in determining the intended function of the chain. On the other hand, it is the size that determines in which sector the chain is to be applied.

As for chains made of stainless steel, they are mainly used in the food sector. They are ideal for being in contact with food and perfect for transporting.

Chains made of steel are chains that need to be treated in order to operate correctly in machines. In addition, chains made of steel have a higher breaking load.

Finally, self-lubricating chains are nickel-plated. Self-lubricated chains have the characteristic of releasing lubricant as the machine runs. Unlike other materials, these chains do not have to be soaked in grease.

For more information about roller chains with attachments and extended pins, please do not hesitate to contact us and ask for information about the chain. See you next time!